Other Products

Count Sunk

Count Sunk

Count Sunk

Count Sunk

Count Sunk

Count Sunk

Products on Sale

About eBolts Australia

Welcome to Ebolts online Store, our goal is to offer you the best value products and range available, and to dispatch them to you as quickly as possible. We want you to have an enjoyable shopping experience that is fast and trouble-free and we hope that you will return to our store regularly.

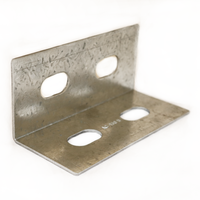

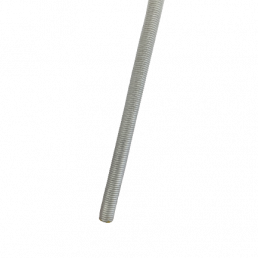

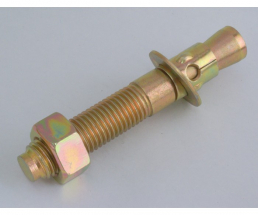

We specialize in metric fastener bolts, nuts, washers, screws, rivets, construction fasteners, allthread, purlin bolts and purlin brackets, chemical anchor studs, driver bits, hex bolts, hex set screw, hex nuts, socket head cap screws, hex head coach screw, coach bolts and nuts, sleeve anchors, wedge anchors, true bolts, hex flange nuts, hex dome nuts, nyloc nuts, flanged nyloc nut, jam nuts, spring washer, and many other items including zinc nut, stainless nut, galvanised nut, screw bolt, stainless bolt and all types of screws and bolts.

Nuts And Bolts Melbourne

eBolts specialises in providing high-quality nuts and bolts in Melbourne along with screws, nails, and other hardware.

Coach Bolt

If you need nuts and bolts, you need to visit eBolts. We have one of the largest selections of nuts and coach bolts available. We have it no matter what size or type of bolt you need. We have a wide variety of nuts to choose from.

We have all standard sizes, but we also carry specialty bolts and nuts that are hard to find elsewhere. If you need it, we probably have it. Our selection is unbeatable, and prices are incredibly competitive. You won’t find a better deal on nuts and bolts than you will at our store. See us today, and let us help you get your project started.

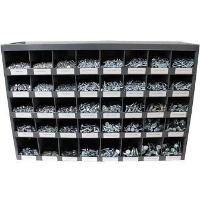

eBolts stocks a wide variety of screws, bolts, and nuts

eBolts have various screws, bolts, and nuts to fit your needs. We carry both standard and metric sizes so that you can find the perfect fit for your project. We also offer a wide range of materials and finishes so that you can get the perfect look for your project. We have a great selection of specialty screws and bolts so that you can find the ideal solution for even the most challenging projects.

Nuts and Bolts Melbourne stocks standard and specialty screws, bolts, and nuts

If you’re looking for screws, bolts, and nuts in Melbourne, you’ll be happy to know that several great suppliers are stocking standard and specialty screws, bolts, and all-thread rods. eBolts is one such supplier with many products, including stainless steel and galvanised screws, carriage bolts, hex bolts, lag screws, and more. Whether you’re a professional tradesman or a DIY enthusiast, eBolts has suitable screws and bolts for the job.

eBolts is a family-owned business supplying screws, bolts, and nuts to Melbourne businesses and consumers since 1987. With over 30 years of experience in the industry, eBolts knows how to provide quality products at competitive prices.

eBolts has a team of experienced staff who are happy to help with any questions or queries

eBolts has a team of experienced staff who are happy to help with any questions or queries regarding nuts and bolts. Whether you need help choosing the right bolt for the job or need some advice on how to get the most out of your hardware, our team is here to help. We have a massive range of products available, so we’re confident we can find the perfect solution for your needs. And if you can’t find what you’re looking for on our website, get in touch, and we’ll do our best to source it for you.

eBolts is a great place to find all of your hardware needs. The staff is knowledgeable and helpful, and the prices are unbeatable. eBolts will be your perfect choice if you want quality hardware at a great price.